Injection Grouting technology is an apt methodology for treating leakages. While treatments at source or on positive side are popular for their lower costs and precision, negative or affected area injection grouting is the modern, advance technology for arresting leakages especially if the source of the leakage is inaccessible or hard to trace.

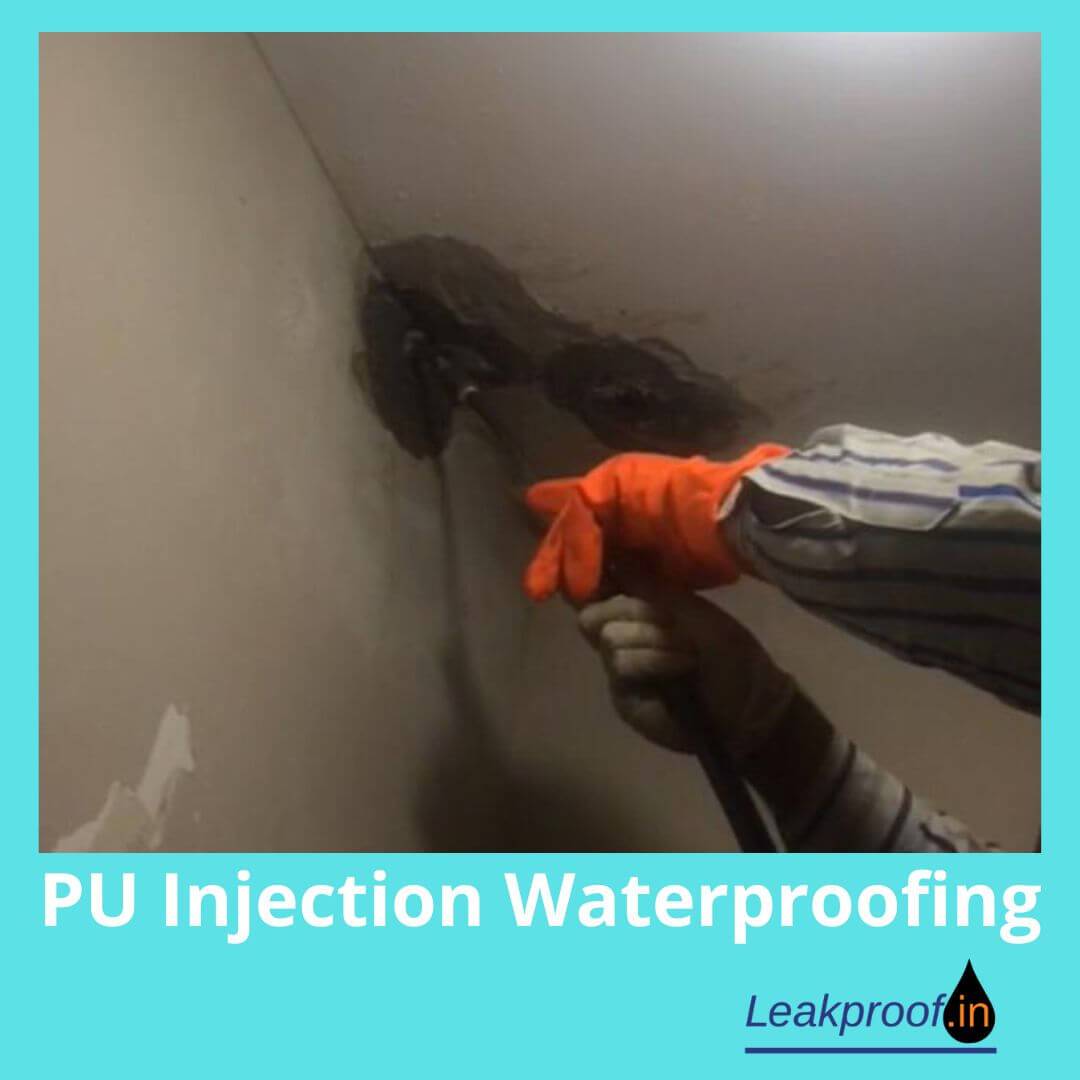

The use of polyurethane is advisable due to its capacity of expanding (on foaming) which helps arrest the leakage along the passage way especially if the leakage is profuse.

Reverse PU injection should be carried out with proper understanding of the built-form, its material and strength and the process should be carried out by skilled personnel only or you can appoint an expert waterproofing contractor in Mumbai. Do watch our you tube video Part-1 and 2

The process involves stages:

- Identifying the spots or locations of the leakage.

- Drilling hole in the built form using hammer drill.

- Inserting the packers and securing its edges.

- Adequately covering the surrounding areas to safeguard against spillage.

- Injecting PU, ideally the following day.

- Check for leakage over the next 24 to 48 hours, re-injecting if required.

- Removing the packer extensions.

While theories thrive around the effectiveness of PU injections, it is highly recommended for sub-structures and leakages extending over long duration of time. There are waterproofing solutions to all types of leakages.